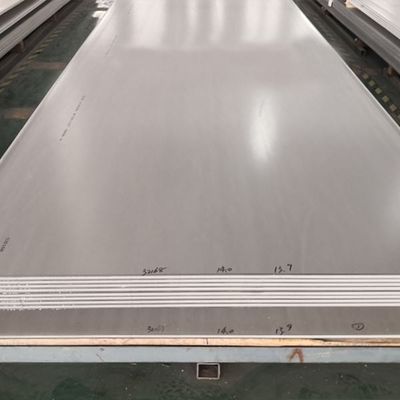

Custom Stainless Steel Sheet Metal Manufacturers 316 2b 302 0.3mm 0.8 Mm 0.5mm 3.0mm For Elevators

| Goods Name | Stainless Steel Sheet | Steel Grade | 301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, |

|---|---|---|---|

| Width | 10-1000mm, Or Customized Size | Thickness | 0.3-3mm Or As Customized |

| Surface Treatment | According To Customer Requirement | Advantage | Strong Corrosion Resistance |

| Application | Chemical,electric Power, Boiler | ||

| Highlight | stainless steel sheet metal manufacturers,custom stainless steel sheet metal,0.8 mm stainless steel sheet |

||

Super Quality Stainless Steel Sheet 316 2b 302 0.3mm 0.5mm To 3.0mm 201 304 316L 410 430 321 For Elevators

Duplex stainless steels allow savings in material costs in corrosive applications such as chemical processing, including chloride- and sulfur-bearing environments. They consist of a mixture of austenite and ferrite in roughly equal proportions. Duplex stainless steels are subdivided into lean, standard, super, or hyper duplex based on the quantity of alloying elements. Duplex stainless steels contain more chromium and less nickel than 300-series and typically include nitrogen as an additional austenite stabilizer and molybdenum for corrosion resistance. 2205 (22% chromium, 5% nickel, and 3% molybdenum) is a common standard duplex stainless steel, and 2507 (25% Cr, 7% Ni plus 4% Mo) is a common super-duplex steel.

The broad array of stainless steels available provides a vast portfolio of capabilities. However, each alloy has distinct advantages and disadvantages. When selecting a grade of stainless steels available it is important to consider how components will be fabricated and joined together, the specific environment to which it will be exposed, in addition to the considerations common to other alloys such as mechanical requirements and cost.

Stainless steel Properties

Stainless steel has many desirable properties that contribute greatly to its widespread application in the making of parts and components across many industrial sectors.

Corrosion resistant

High tensile strength

Very durable

Temperature resistant

Easy formability and fabrication

Low-maintenance (long lasting)

Attractive appearance

Environmentally friendly (recyclable)

Above all, because of its chromium content, it is extremely resistant to corrosion. The 10.5% minimum content makes steel approximately 200 times more resistant to corrosion than steels without chromium. Other favorable properties for consumers are its high strength and durability, its high and low temperature resistance, increased formability and easy fabrication, low maintenance, long lasting, attractive appearance and it is environmentally friendly and recyclable.

Once stainless steel is put into service, it does not need to be treated, coated or painted.

| Product Name |

Stainless Steel Sheets

|

|

Place of Origin

|

China

|

|

Width

|

3mm-2500mm or as required

|

|

Thickness

|

0.03mm-300mm or as required

|

|

Length

|

as required

|

|

Technique

|

Hot rolled / cold rolled

|

|

Surface Treatment

|

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D or according to customer requirements,etc.

|

|

Material

|

201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L

|

|

MOQ

|

5 Tons

|

|

Inspection

|

Fully accept all the third parties to test before shipment.

|

|

Export Packing

|

Waterproof paper, and steel strip packed.

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required. |

| SURFACE | PROCESSING METHODS | APPLICATION |

| NO.1 | The surface is finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate lustre. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| 8K | The product is continuously processed with 1000# abrasive thus, it is with high gloss and reflection properties. | Construction,mirrors,plate sets,decorations,ect. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

![]()

Before- Sale service:

1. ISO Verified Outstanding Manufacturer

2. The third party inspection: SGS, BV, CE, COC, AI and other.

3. Flexible Payment: T/T, LC, O/A, CAD, DAP, KUNLUN Bank

4. Sufficient Stock

5. Quick Delivery Time, Long time price validity.

6. Tracking picture of transport: Production, Loading and reinforcement loading Pictures

7. Rich experience Professioal Sale Team

After- Sale service:

1. Quality Guarantee after Receiving the Goods:

Offer money return or Ship new products for free if any problems happen

2. Technical Guidance for further Processing

3. VIP Service and Free Order after Accumulated Order Quantity

FAQ

Q1: Are you factory or trading company ?

A: Best quality is our principle all the time. We have 2 times QC one by one.

Our vision: to be world-class professional, reliable and outstanding steel supplier.

Q3: Do you provide samples ? Is it free or extra 2 ?

A: The sample could can provide for customer with free, but the freight will be covered by customer account. The sample freight will be returned to customer account after we cooperate.

Q4: What is your MOQ ?

A: We welcome your trial order MOQ 25 T to be stuffed in 1*20GP

Large quantity can reduce your cost.